The reason why foiling services are so popular is because of the appearance they bring to a wide array of items. If you compare to standard ink, metallic foil is also more appropriate for a much greater number of surface types. For you to get the greatest results here though, you need to work with an expert team like ours.

Many people ask the question

Have you ever thought about why your aluminium foil has two sides that look different? You are not the only one. Many people wonder the same thing. To help you understand, we will be diving more into this subject here. We will tell you why one side is shiny while the other is dull.

Have you ever thought about why your aluminium foil has two sides that look different? You are not the only one. Many people wonder the same thing. To help you understand, we will be diving more into this subject here. We will tell you why one side is shiny while the other is dull.

To begin with, this isn’t a marketing gimmick or some variety of secret technique. It is merely the result of the manufacturing operation of aluminium foil, which leads to separate appearances on the two sides. One is matte or dull and the other is shiny.

The manufacturing process

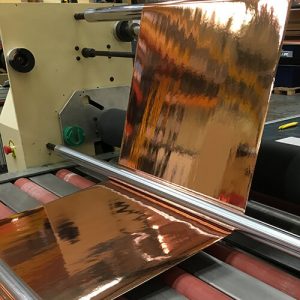

This consists of rolling aluminium slabs that were cast from molten metal. It is performed in a rolling mill so the manufacturer can achieve the necessary thickness for the foil. The milling process leads to differences on each side.

During the manufacturing, the machine will apply tension and heat to stretch the foil and get the necessary size and shape. To prevent it breaking, it is a good idea to press two layers of the foil together and mill them at the same time. Finally, separate the two layers, making them ready to use.

The side that came into contact with a separate layer of foil turns into the dull side. As for the side that got milled without coming into contact with the other foil, it becomes the shiny side. It is merely because of the current methods of producing aluminium foils that it has these sides. Contact us if you need first class foiling services.

The only real difference

As for whether there is a difference between the two sides, it is a debate that has been ongoing for a long time. People bicker over the “correct” side of the foil. In reality, there isn’t one. You are free to use either for your purposes. The only real difference would be the non-sticking coating. The dull side tends to be more non-stick. If your application needs a non-stick foil, make sure you use the dull side.

We want to meet the highest standards with foiling services

Our main goal is to achieve the very best results every time we work on a project. You may wish for us to create a foiling style for you, or you could already have something in mind. Whatever the case, we will be able to help you create the perfect products.

So, if you would like to take advantage of our foiling services, please let us know. We can give you a great service using the best materials.