Foiling services are able to benefit your items in several ways, whether they are marketing materials, decor, or something else. However, you won’t get the full benefits if you choose a low quality service. We have been working in this field for a long time. As a result, our team has built up a huge wealth of experience. So, we can provide the ideal experience every time.

How does cold foiling work?

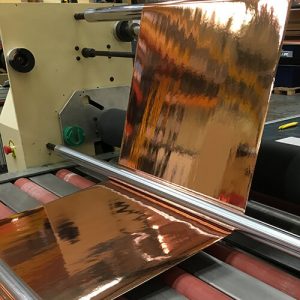

One well known foiling technique you can use is cold foiling. It is a swift and cost effective on-press technique. You use it to introduce foils to a myriad of substrates. At times, it is known as foil printing.

One well known foiling technique you can use is cold foiling. It is a swift and cost effective on-press technique. You use it to introduce foils to a myriad of substrates. At times, it is known as foil printing.

During this procedure, you apply the cold foil to an adhesive image via a standard printing plate. Your foil gets affixed to the printed adhesive, generating an image before the application of printing inks. The foil that does not stick to the adhesive stays on a thin polyester liner. As for the waste, it goes to a rewind spool.

The adhesive here gets applied on press similar to an ink. Therefore, you don’t require a stamping die. After printing, the cold foil image surface often gets a varnish coat to supply you with a durable surface. Since it uses a printing plate, the registration between your printed inks and varnish, and the foil is press perfect.

As you can see, this is a useful technique. But, we want to go further by comparing it to metallised substrates. These come ready to print. To gain high-impact metallic coverage, the substrates provide top tier brilliance. Choosing between the substrates and cold foil shall depend on a number of factors.

Length and coverage

You are able to purchase metallised substrates in web or sheet form. However, the extra expense massively increases the final cost of your project. Even so, for huge runs with complete metallic coverage, they tend to be the most cost efficient decision. As for light-to-moderate coverage and/or short-to-medium runs, you will probably be better off with cold foil. If you require first rate foiling services, please contact our team.

Whites

If whites, bright or light colours, or skin tones are crucial to your design, you can achieve them easily with cold foils. You simply have to “knock out” the foil areas. As for metallic substrates, you have to apply an opaque white before the print layer. It will need extra print units too.

Colours

Lastly, there is colours. With either metallised substrates or cold foils, you can achieve a limitless amount of options by overprinting them.

Nobody does foiling services better than us

At Foiling Services, we understand all the finer details of foils. We know that this is a complex process that is easy to get wrong. Therefore, we are very careful whilst handling items and applying foil. This ensures you get the best results.

You can use our foiling services for protective or decorative purposes on lots of different products. So, get in touch with us today if you want to give them a try.