Foiling services have many advantages that make them valuable to businesses in lots of industries. Some people simply want their items to look better. Others aim to ensure their goods stand out from everything else. No matter the reasoning of our own clients, we provide them with a top quality solution.

Everything must stay in top condition

One of the main reasons we can offer such high quality services is we have top of the line equipment. In addition, we work hard to keep it in pristine condition. Frequent servicing and cleaning is essential to preserving hot foil mechanisms. We have several tricks and tips to share with you that shall prove useful if you have your own machines to take care of.

The right cleaning products

Cleaning the primary body of your machine demands no specialist solutions or liquids. Standard household furniture polish will do quite nicely. Spray this onto a soft cloth and then wipe any foil dust or grime away gently. Avoid putting the polish onto the press directly. As for the moving components, you can employ 3 in 1 oil. However, we advise that you use this sparingly. Use too much and you can make a big mess.

Attend to magnesium and copper dies

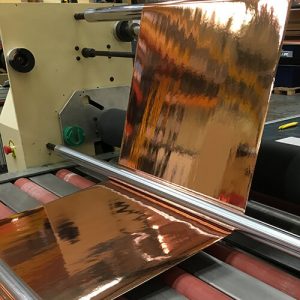

Another point we need to make is that keeping your foiling dies clean is vital. This is especially true for ones made of copper and magnesium.

Another point we need to make is that keeping your foiling dies clean is vital. This is especially true for ones made of copper and magnesium.

We will start with the magnesium varieties. For these, you should use a soft show brush to dispose of paper debris. Using other techniques can round the block’s edges and therefore make the letters seem less sharp.

Next, we come to copper dies. They are made of stronger metals than their magnesium counterparts. Since this is the case, you need to clean them a tad more harshly. A glass fibre brush can get rid of minor imperfections on the die’s exterior. This shall aid you in guaranteeing that the foil finish has consistent quality.

Look after your brass dies too

It is also important to know how to handle brass dies. Here, you are free to use a brass cleaning brush to deburr, polish, and clean the die safely. You can do this without worrying about damaging it. Moreover, you can use these brushes to clean electrostatic parts like circuit boards. For the finest foiling services in the country, please call us.

Servicing and checks

General regular servicing and checks are also crucial here. Every six months, you should confirm that the foil feed and toggle link parts on the mechanism are tight. With frequent servicing, you will keep your press in prime condition and minimise breakdowns. Other effects of this include increasing efficiency and preserving productivity. In short, all this work is well worth your time and effort.

Come to us for foiling services

We are proud to use our skills to deliver stellar results to every client. This may seem like a simple process. However, when someone gets it wrong, the results could be disastrous. Therefore, it is preferable to take the professional route with us.

If there is anything Foiling Services can do for you, please let us know. We love taking on all kinds of projects and also have access to the highest quality foils and laminates.