Foiling services can provide users with all sorts of benefits. In order to obtain them though, you will need to work with experts that know what they are doing. Our team has more than a decade of experience in providing high calibre results. This is the case for laminating as well as working with foils. As a result we can offer consistent, high quality services.

There are many possibilities

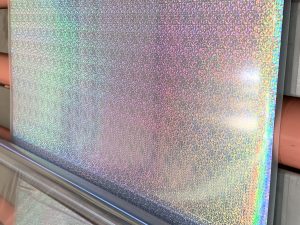

These days, there are numerous things you can use to add multi-sensory effects to packaging. Because of this, brands in all sorts of industries are branching out more and using foils. However, the difference between cold and hot foil is one of the main areas of confusion. What we are going to do is dive into this subject and talk about foil coverage and some of the substrate considerations.

Foil coverage

For the majority of applications, you can use the cold foil operation inline on your printing press. The image area could be compact and it might not use most of the foil roll over your sheet. If this is the case, there can be considerable levels of waste in foil. In comparison, the hot foil procedure allows the foil roll to accurately index in small gains. This maximises the use of the whole foil ribbon.

For the majority of applications, you can use the cold foil operation inline on your printing press. The image area could be compact and it might not use most of the foil roll over your sheet. If this is the case, there can be considerable levels of waste in foil. In comparison, the hot foil procedure allows the foil roll to accurately index in small gains. This maximises the use of the whole foil ribbon.

In cases where most of the sheet or the whole thing includes foil, cold foiling can become a cost efficient option. Huge coverage on the sheet shall permit you to gain maximum usage of the foil ribbon. Furthermore, the project may demand several foil colours. If yours does, cold foil shall become the more economical choice. This is because everything gets done in a single pass and is overprinted to produce the different colours. For top quality foiling services, please speak to our team.

Saving foil does not mean saving money

Another vital fact to remember here is that saving foil does not necessarily result in job cost savings. You must see the full picture. Something many individuals don’t realise is that job costs include the logistics, process, and additional materials. It is crucial that you always look beyond the costs of the foil material.

The substrate considerations

As for these, you need to remember that some substrates can create obstacles for cold foil. Uncoated stocks are a good example to use here. During the operation, you introduce a layer of adhesive to the sheet. Uncoated stocks have a habit of absorbing the glue. The result is less adhesive for your foil to stick to when you apply it. What you end up with here are uneven surfaces, flaking foil, and rough edges.

With hot foil, you have more latitude with the substrate varieties. This is because you introduce the foil with a heated application onto your sheet rather than using adhesive.

As you can see, the form of substrate or stock can have a large effect on choosing between the two foils. You should keep it in mind and choose which option you think will produce the right finish.

Foiling services from an expert team

We are more than capable of tackling this complex process. We know that one wrong move is all that it takes to ruin everything. Using our training and experience however, we will meet your needs and ensure this does not happen.

Contact Foiling Services today if you would like to work with us. We can discuss all the different foil options we have for you, including the wide choice of foils from reliable brands.