We have many years of experience working with foiling services. This has given us the knowledge and skills to meet all our customers’ requirements. In addition, for higher quality results, we have the best foil machinery available. Whatever it is you require, out team will work hard to achieve it for you.

Making your packaging sophisticated

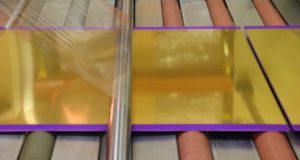

When you use metalised decorating techniques, you can provide your packaging with a sophisticated, distinct look. The undeniable gleam, which you can notice even on busy shop shelves, easily attracts customers. Since shiny metals are typically valuable, it is able to generate a subconscious link. People will think that whatever is in the packaging is also valuable.

You may be planning to produce such a look for your own packaging. If this is the case, you can find yourself at a crossroads. Metalised inks and hot foil stamping are among the most popular options. But they are entirely different procedures and have differing effects. You are probably wondering how you decide which one is most suitable. We are going to explain both practices in detail below.

Hot foil stamping

This technique is one of the oldest ways of generating metallic finishes. Such a long history has given sufficient time for technological advancements. As a result there are lots of options here. For example, it is possible to stamp an extensive collection of reflective areas. You can create fine details or foil extremely large surfaces.

This technique is one of the oldest ways of generating metallic finishes. Such a long history has given sufficient time for technological advancements. As a result there are lots of options here. For example, it is possible to stamp an extensive collection of reflective areas. You can create fine details or foil extremely large surfaces.

In terms of how it works, it is all about heat and pressure. Both work in tandem to move thin foil straight onto your paper stock. The heat is able to activate special adhesive coatings so the foil will adhere to your substrate.

One of the benefits here is that it is environmentally friendly. A study by the Foil Stamping & Embossing Association did testing on foil board and paper. It found that both cold and hot foil stamping operations were repulpable and recyclable. This is an excellent benefit if you are trying to attract environmentally-conscious buyers.

Another benefit is that it creates a texture effect. You apply hot foil stamps directly on top of printed materials as an individual element. Due to this, they produce a metal-like, smooth feel. It engages the sense of touch of customers. The products will demand to be felt. By foil stamping directly to embossed elements, you can augment the effect. Come to us if you require the best foiling services available.

Metalised inks

You create these particular inks by introducing real metal particles to a specific type of ink. When you add them to packaging they reflect light and offer a distinct shine.

One of the largest distinctions between this and hot foil stamping is that you apply the inks early. It may take several coats to obtain the necessary look. Afterwards you will coat your ink in a finish of some kind, such as varnish or lamination.

The ink is a good choice for subtle effects. Because of how everything works, the result isn’t as dramatic as foiling.

Comparing

When attempting to decide between hot foil stamping and metalised inks, keep certain things in mind. This includes your schedule, speed to market, cost, and area coverage.

If your aim is to minimise waste and maximise foil area coverage, hot foil stamping is the way to go. It makes use of most of the foil ribbon by indexing compact increments. This limits the waste.

Finally, you should keep your schedule in mind. Ensure you can get onto the market on time. If you fall behind, your company is going to lose valuable revenue. Foiling can be a faster option.

Work with our team when you need foiling services

We know that the work we do can deliver outstanding results. But, we know adding foil can have the opposite effect when done incorrectly. As such, we take steps to ensure this does not happen.

So, if you’d like to experience our foiling services for yourself, please speak to our team. We can advise you on how to use them in various projects.