Many establishments have sustainability goals they intend to reach by 2030. However, the fact is that KURZ, our partner, is already leading the way with completely innovative solutions. They are ones that promote the environmentally friendly production of sustainable foils. It makes them a global leader.

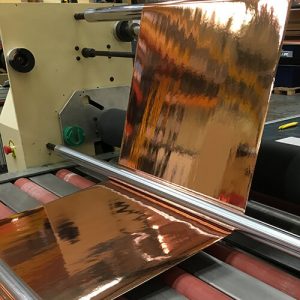

The foil production offers a decisive competitive edge for KURZ. It minimises the materials they utilise and introduces multi-use technologies to their finishes. In addition, they have the RECOSYS recycling program to minimise waste.

The foil production offers a decisive competitive edge for KURZ. It minimises the materials they utilise and introduces multi-use technologies to their finishes. In addition, they have the RECOSYS recycling program to minimise waste.

What started out as a genuine challenge has managed to produce exceptional results. It has become a game changer in the foiling industry. KURZ has been able to streamline the carrier material. Also, they now accept returns of considerable PET, and remanufactured and reused ready-to-melt granulate. There is a clear sustainability principle here. It is one that concentrates on preserving resources and being efficient.

Resource conservation

With eco-friendly production, one of the leading issues is resource conservation. In 2023, KURZ is launching a revolutionary slimming drive. It aims to lower the level of waste when introducing finishes to print products and labels. Their slim surface sustainable foils provide users with the performance and attractive look people know them for. All this comes while they lower the quantity of material they are using.

To talk more specifically, the PET substrate material will go down from 12 µm to 6 µm. This will reduce the amount of plastic they use.

In addition, users can obtain cost advantages here. Due to the lower thickness, every roll will be able to hold more running metres of usable decoration. This means extra time for adding the finishing touch and less of it spent on replacing rolls. Please get in touch with us if you would like to know more about sustainable foils.

No more wasting raw materials

You are probably not a fan of wasting raw materials. With KURZ RECOSYS they provide a return and recycling set up. It re-processes the raw material from the PET carriers, making it the planet’s first operation that makes transfer film residues recyclable.

Normally, PET carriers lose significance after you apply the transfer decoration to the item. In most cases they end up as industrial refuse. But, as an eco-conscious trendsetter, KURZ wondered if that was the best they could accomplish. They didn’t want to leave such valuable raw material to waste away. Instead, they used their expertise to come up with a fresh recycling system for the PET.

As for how it functions, you can use this system to manufacture both monomers and recyclables for PET polymerisation. It converts the transfer films into a first rate injection moulding material.

Work with our team if you want to use sustainable foils

At Foiling Services, we perform all our foil work with skill and precision. Our goal is to maximise the quality here. A big part of that is we start off with the finest foils, including materials from KURZ. You can expect us to offer a broad range of choices without the restriction to standard shades of gold and silver.

We would be happy to help you choose the best decorative services. So, contact us if you would like to know more about our work or sustainable foils.